FIT FOR THE ROAD, FIT FOR THE TRACK

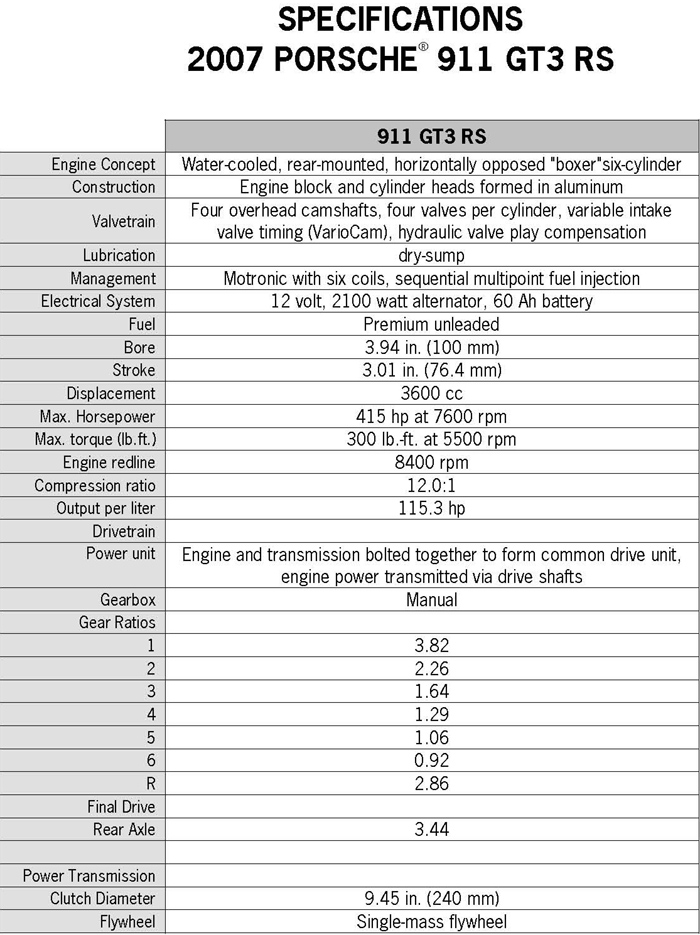

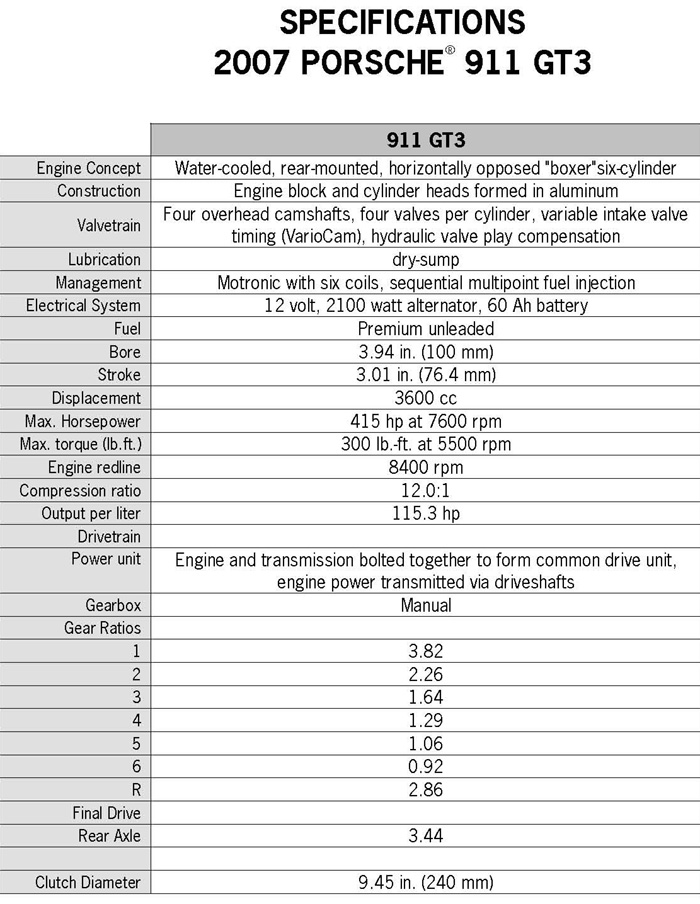

An automotive athlete conditioned at the track, the 415-horsepower 911 GT3 is Porsche’s most-powerful naturally aspirated 911 Bred for the enthusiast driver who craves track days as much as street drives, the 2007 Porsche 911 GT3 is as at home at Clubsport events as it is in everyday traffic. Powered by a 415-horsepower, 3.6-liter Boxer six-cylinder, the raceinspired engine reaches its maximum output at 7600 rpm, on the way to a lofty 8400 rpm redline.

These specs place Porsche’s flat-Six power unit at the specific-output pinnacle for current naturally aspirated production cars. The engine’s high-revving characteristics are made possible by the concentrated reduction of moving masses in the engine, with further optimization of air flow making significant contribution to the increased output. A variable-length intake manifold, combined with a larger, 82 mm throttle butterfly, optimized cylinder heads and exhaust system with lower back-pressure significantly reduce flow resistance versus the former model, improving the cylinder charge cycle. Some other tech highlights of the new 2007 GT3 include:

Optimized exhaust system

An extra-large main muffler with central tailpipes and two pre-mufflers controlled via the exhaust gas butterflies reduce the exhaust gas back-pressure. Compared with the previous GT3 model, overall capacity of the new exhaust system is up 12 liters. At the same time, the 911 GT3 fulfills all noise and exhaust emission limits under the LEV II and Euro 4 standards, while still offering the incomparable sound of sporting performance.

Six-speed manual gearbox with gear spacing tailored to the car

The six-speed manual gearbox now provides shorter transmission ratio increments, taking the extended rev-range of the GT3 engine into account. On the road or track, this means acceleration from 0-62 mph (0-100 km/h) in just 4.3 seconds, with the GT3 charging on to 99 mph (160 km/h) in 8.7 seconds. Top speed is 310 km/h or 193 mph.

Active suspension for an even wider range of driving dynamics

With Porsche Active Suspension Management (PASM) available for the first time, on GT3 it’s been tuned for motorsport, and offers two sporting set-ups in one. The standard setting is fundamentally the same as on the previous generation GT3, and is most suitable for roads with bumpy, or non-smooth surfaces. In Sport mode, the system switches over to a firmer damper setting particularly well suited for track work or smoother surfaces.

Low weight for supreme agility

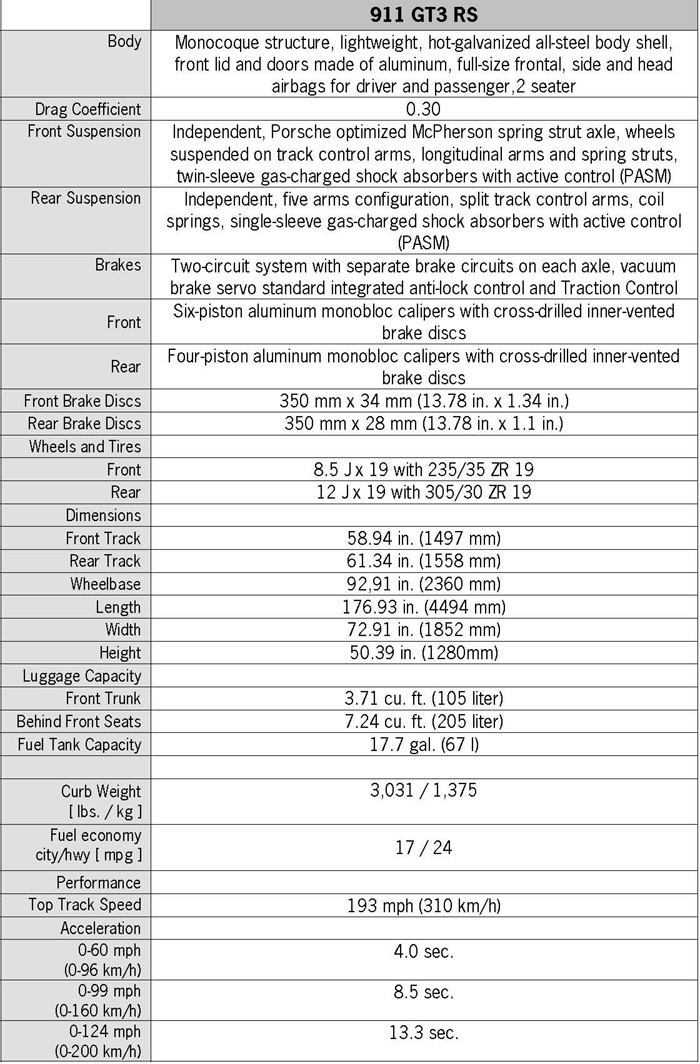

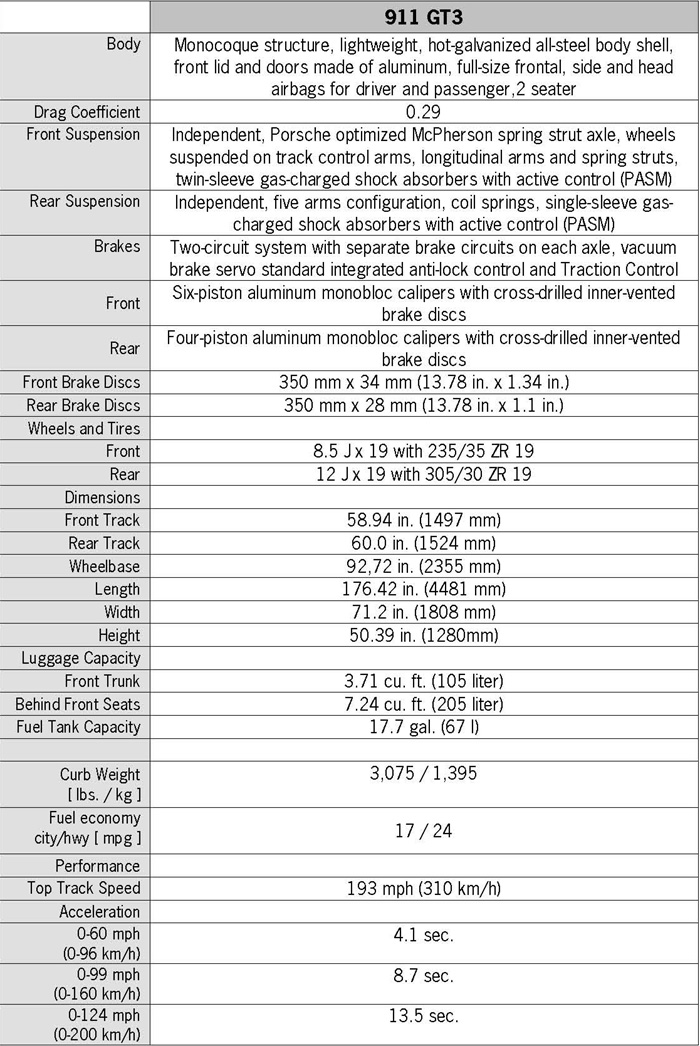

All parts and components of the 911 GT3 are designed to convert the power of the engine and the qualities of the suspension into optimum driving dynamics on the road. This is aided in particular by the car’s low weight of 3076 pounds (1395 kilos), the dedicated tuning of the PASM, the increased performance of the brakes, and the new sport tires. On the track this means even faster lap times, while in everyday motoring this equates to supreme active safety.

Traction Control now standard

The combination of the standard sport tires, and the mechanical/electronic limited-slip differential enables the driver to effectively transmit the power and muscle of the GT3’s engine to the road, enabling maximum traction at all times. To provide such capabilities, Traction Control ties together three electronic control systems: Automatic Brake Differential (ABD), Automatic Slip Control (ASC), and Engine Drag Control (EDC). Masterminded by an electronic “brain”, the Traction Control offers two different control maps, can be completely deactivated, and features both wheel-spin and drag-force management for extra smoothness. The limited-slip differential offers an asymmetric limited-slip function of 28 percent under load and 40 percent in overrun.

Improved aerodynamic balance

The new GT3 is naturally built for superior safety even at very high speeds. Effective downforce is therefore ensured by both the front air dam and the rear wing, with the sporting design and shape of the body reducing the car’s drag coefficient to an impressively low 0.29.

The GT3 in Detail

Track bred, street ready

The Porsche 911 GT3 is the most direct link between a road-going sports car and a track-proven racing car. Conceived, designed and built for undiluted driving dynamics, the drivetrain, suspension and aerodynamics of the car provide a unique synthesis of everyday driving qualities and thoroughbred racing technology. The heart of the new Porsche 911 GT3 is of course the six-cylinder boxer engine. Originally built for the Porsche 911 GT1, this exceptional engine has proven its qualities time and again throughout several stages in the evolution process, boasting the same technology and engine features in the Porsche GT3 Cup, the GT3 RS, and the GT3 RSR. Developing a specific output of 115.3 bhp per liter, this power unit ranks at the top of all normally-aspirated engines in cars currently homologated for road use.

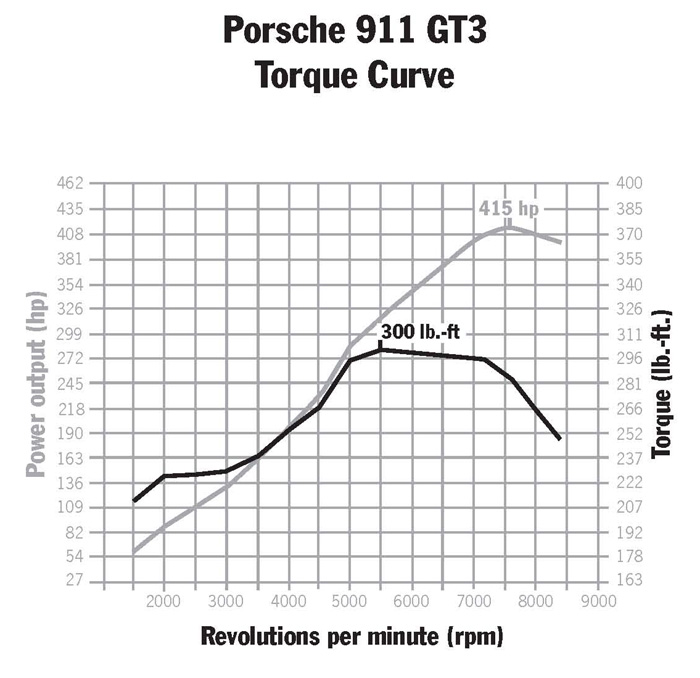

This performance is the result of a consistent, far-reaching process of ongoing development seeking to increase engine output without increasing the size of the engine itself. Displacing exactly 3.6 liters, the six-cylinder featured in the new 911 GT3 capitalizes on the displacement limit allowed in its category of motorsport, developing 415 bhp at 7600 rpm and reaching a maximum engine speed of 8400 revs. Peak torque, in turn, is 300 lb-ft at 5500 rpm. By comparison, the former 911 GT3 developed maximum output of 381 bhp at 7400 rpm and peak torque of 284 lb-ft at 5000 rpm. Over and above the efficient power and torque of this extremely compact engine, the new 911 GT3 excels in its quick-revving qualities and immediate response throughout the entire rev range.

Lightweight technology promotes a high-revving powerplant

The objective in developing the engine was to enhance the high-revving concept. To reach even higher engine speeds, Porsche’s engineers have reduced mass and the mechanical loads acting on the engine’s moving parts. On the new GT3, this applies most directly to the pistons, connecting rods, and crankshaft. The result of these improvements is an increase in maximum engine speed from 8200 rpm on the former GT3 to 8400 rpm on the 2007 911 GT3.

The improvements made on the forged pistons involve not only the new shape of the pistons, but also the size of the piston pins, which have been reduced in diameter by 1 millimeter to 21mm. This adds up to an overall reduction of weight on each piston (including the pin) of approximately 30 grams. A further improvement is the re-design of the piston crown for enhanced combustion. To increase maximum engine speed, the titanium connecting rods have been extended in length by 1.5 millimeters to 131.5mm. This allows a smoother transition of reciprocating force from the connecting rods to the crankshaft, while reducing loads acting on the various components.

Since the upper conrod opening now houses a thinner piston pin than before, the entire connecting rod is also thinner. Weighing just 418 grams, the titanium connecting rods are approximately 150 grams lighter than comparable steel rods. In the process of revising the crankshaft, which runs in eight main bearings, Porsche’s engineers concentrated on optimizing the shape and design of the crankshaft webs to lighten the structure by 600 grams. This allows higher engine speeds, but also improves the engine’s response. The crankshaft bearings are now also hardened in a nitro-carbonating

process.

Dry sump lubrication for the toughest racing requirements

As before, Porsche’s classic dry sump lubrication system with a separate tank ensures a reliable supply of oil to the engine even under the extreme conditions encountered on a race track. The oil pump is driven by the crankshaft via a layshaft and a connecting shaft. The pump itself is made up of three segments, one of which is responsible for supplying compressed oil to the engine. This supply unit extracts engine oil from a separate oil tank, sending the oil through an oil/water heat exchanger and oil filter before continuing into the engine oil circuit. The other two pump segments draw out the oil accumulating in the crankcase and pump it back to the oil tank. The increase in power and performance obviously means higher temperatures and thermal loads within the new GT3 power unit. To offset these higher temperatures, Porsche’s development engineers have opted for a larger water pump and a radiator with larger surfaces.

Engine block in sandwich structure

The engine block is fundamentally the same as that of the former GT3 power unit, meaning that it is built in a sandwich structure. The cylinder cases, cylinder head and camshaft cases of each row of three cylinders on the right and left side are combined to form one unit, to increase the torsional stiffness within the engine. Unlike the engine in the 911 Carrera®, the cylinder cases are not connected with each half of the crankcase. This is because the power unit of the GT3 serves as a homologation engine for motorsport, and this elaborate configuration was chosen in order to respond quickly to any changes in engine-size categories.

The cylinders cases are made of a light alloy featuring aluminum, with Nicosil-coated liners. In the interest of more efficient combustion as well as enhanced fuel economy, the compression ratio has been increased from 11.7:1 on the previous-gen GT3 to 12.0:1 on the 2007 model. The cylinder heads are made of a temperature-resistant light alloy, and are nearly identical to the cylinder heads on the former model. The exhaust valve rings are now cooled directly by coolant running through an additional duct, and heat dissipation is enhanced with sodium filled exhaust valves. The valves are precisely engineered for minimum tolerance and interact with cup tappets also optimized for minimum weight and feature hydraulic valve play compensation. To ensure that the valves always close properly even at lofty revs, both the intake and exhaust valves feature double valve springs. The finishing touch is polished intake and exhaust ducts to provide minimum resistance in the gas charge cycle.

VarioCam operating over a wider area of adjustment

The valves are controlled by hollow-cast camshafts, with the intake camshafts being adjusted infinitely by VarioCam management, and the valve timing on the intake side being modified accordingly. This adjustment no longer uses an axial adjusting mechanism, but rather a vane-cell adjuster of the type featured in the current 911 Carrera. The big advantage of the new system is that intake camshaft adjustment is now up from 45-degrees to 52-degrees, further enhancing the engine’s qualities in terms of output, torque and emission management. The intake camshafts have also been revised, with intake valve stroke increased by 0.4 millimeters over the previous model to 12.7mm. The cam contours and exhaust valve stroke of 11.1mm remain unchanged.

New variable intake manifold with two resonance flaps

A new variable intake manifold boasts two switchable resonance flaps made of aluminum, the material chosen to increase the strength and precision of their complicated geometry. With its smooth surfaces and large cross sections, the flowefficient intake manifold ensures a larger cylinder charge. Reflecting the same high standard, the air collectors and intake pipes on the new 911 GT3 are carefully finished for optimum smoothness and feature extra-large dimensions.

Apart from flow dynamics, the air resonance pulsing within the intake manifold must be put to optimum use to ensure a good cylinder charge. This is handled by a switchable connection pipe, with resonance flaps coordinated by the engine’s Motronic control unit. The process of the valves opening and closing, as well as the movements of the pistons, excites the air in the intake manifold and serves to build up the oscillation required. The degree of such oscillation depends on engine speed and the inherent resonance of the intake system. The oscillating air is then used to ensure an optimum air charge in the cylinders, again contributing to the engine’s increased power and torque.

With oscillation varying as a function of engine speed, the resonance of the intake system has to be changed from time to time in order to build up a new resonance. This is done by opening or closing the connection pipe in the intake system. A multi-stage intake system with several resonance flaps allows use of the resonance effect throughout a wide range of engine speeds. To ensure a smooth and consistent torque curve, the new 911 GT3 comes with a carefully devised switching strategy for the resonance flaps. Both flaps remain closed at low and medium engine speeds. The first resonance flap opens at approximately 5400 rpm, exposing the small connection pipe in the process. The small pipe then closes at approximately 6350 rpm and the second resonance flap opens up the large connection pipe. This intelligent management of the system ensures a muscular torque curve throughout a wide engine-speed range, and helps maximize engine power.

Fan-type manifolds with catalytic converters close to the engine

To optimizing the gas charge cycle, Porsche’s engineers have given their full attention to the exhaust system, which is new from the ground up. Gas initially flows through two fan-type manifolds offering the advantage of lower flow resistance and an improved mixing effect. This helps to improve treatment of raw emissions before being converted in the catalyst further downstream. The catalytic converters on the new GT3 are no longer arranged crosswise beneath the rear end of the car, but rather sideways directly behind the manifolds.

This position close to the engine serves to warm up the catalysts more quickly, ensuring a rapid response and thus reducing exhaust emissions particularly when starting the engine cold. As a result, the Porsche 911 GT3 fulfills both the current Euro 4 emission standard as well as the LEV II limits required by law in the USA. Following the two catalytic converters, exhaust gas flows into two new pre-mufflers controlled by the engine’s map control system.

This control function incorporates two flaps downstream of the catalytic converters which can guide exhaust gases either into the pre-mufflers or directly into the main muffler beneath the rear end of the car. Once the exhaust gas flaps open up they provide a direct link to the main muffler and exhaust gas back-pressure decreases by approximately 8 percent compared with the former 911 GT3. The exhaust gas flaps are controlled as a function of both load and engine speed, meaning that the flaps are closed when starting the engine, but open up as soon as the driver calls for more power. In both cases – with the flaps open or closed – the new 911 GT3 fully complies with the noise emission standards required by law.

The system is not only 12 liters larger in capacity, which means lower exhaust gas back-pressure and, as a result, more power, but is also 8.5 kilos or 18.8 lb lighter than the previous GT3. This is attributable to the single-shell, weightoptimized structure, with thinner walls incorporating reinforcement ribs and arched sections for greater strength. A further advantage is the higher degree of system integration: The exhaust gas manifold and catalyst housing are now integrated to form a common unit. A final, and equally important aspect of the new configuration is the characteristic, rumbling sound of a truly sonorous six-cylinder.

Six-speed gearbox with shift-up display

Power is transmitted in the 911 GT3 by a manual six-speed gearbox, which is the sole transmission offered. Based on the gearbox in the former GT3, the new gearbox is specially matched to the torque curve of the new power unit, with shorter transmission ratios on gears 2-6 in the interest of improving acceleration. A new shift-up display illuminates in the tachometer shortly before the engine reaches its shift point, helping the driver find the optimum speed for shifting gears. In consideration of driver-response time, the display illuminates sooner in lower gears than in upper gears, so that that when the driver approaches higher engine speeds in the higher gears, this visual signal is even closer to the engine’s cut-off speed. The overall transmission ratio on the new 911 GT3 is 15 per cent shorter than on the previous model and 22 per cent shorter than on Carrera models. Since the new 911 GT3 was conceived from the start also for racing on the track, transmission ratios may be varied by exchanging gears. This option is intended exclusively for racing purposes on closed tracks and circuits, and not for regular road use.

Limited-slip differential with an asymmetric effect

The new 911 GT3 comes as standard with an asymmetrically operating limited-slip differential. Taking both the higher power of the engine into account, as well as the greater requirements made of the components and their inherent strength, the gears have been reinforced to an even higher level of strength and stability than the gear units on the former model. The GT3, thanks to its rear engine configuration and appropriate weight distribution, requires only a 28-percent locking factor when driving under load. A higher locking factor would merely impair the car’s smoothness and handling in bends, without significantly improving the car’s traction qualities, since the inner wheel might then easily lose its grip prematurely when accelerating. The locking factor on overrun is 40 per cent, and this higher figure is chosen for two reasons. First, because the drag forces generated by the engine are lower than the maximum torque delivered by the engine. Secondly, this configuration serves to stabilize the car under load change in a bend. A further advantage is that the brakes act evenly on both rear wheels when the driver takes his foot abruptly off the gas pedal.

Traction Control derived from Carrera GT

To optimize traction and driving stability, the new 911 GT3 features not just a limited-slip differential, but also on-demand Traction Control (TC), similar in its features and qualities to the system on the Carrera GT. TC comprises the ABD (Automatic Brake Differential), ASC (Automatic Slip Control) and EDC (Engine Drag Control) functions in a single unit. This means that in conjunction with the anti-lock brakes, the new 911 GT3 now comes with a system able to stabilize the car when both braking and accelerating. TC helps to keep the car properly on path and ensures stable driving behavior particularly in bad weather such as rain or when running on road surfaces different from one side of the car to the other. With the drive wheels spinning, ABD will cut in first, applying the brakes on the wheel with higher slip.

Should both wheels be spinning, ASC will cut in within fractions of a second, intervening in engine management to take back engine power by reducing engine drive forces on the gas pedal as well as the ignition angle, until both wheels have re-gained their traction. The ASC telltale will flash on the instrument cluster as soon as the system becomes active, with ASC remaining fully operative and cutting in when required while accelerating throughout the car’s entire speed range. A special function within ASC is Engine Drag Control or EDC for short. This control system cuts in, for example, when after downshifting on a slippery surface, the rear wheels threaten to lose their lateral stability. In such a situation the control system responds quickly by automatically applying throttle and reinstating the car’s driving stability. The driver has the option to deactivate the system completely by pressing the TC OFF button. In this case the driver is informed accordingly by the ‘TC OFF’ telltale coming on in the instrument cluster display.

First GT3 with Active Suspension, Sports mode boosts power

The 2007 911 GT3 is the first to arrive standard with active suspension (PASM). Each damper is individually adjusted by the active suspension management system, and the set-up in the GT3 is matched to the requirements of this special model. The primary objectives were to give the car extremely sporting behavior with an additional handling setup for the track. Like on Porsche’s other models, PASM offers two suspensions in one: The standard setting offers the sporting performance and agility typical of the GT3 with an acceptable level of everyday motoring comfort. This means a high standard of driving dynamics on public roads and on race tracks with varying surface conditions such as the Nürburgring’s Nordschleife (North Loop).

To enhance driving safety at high speeds, the dampers automatically switch over to a firmer setting as road speed increases. Set to the Sports mode, PASM allows a more precise driving style by reducing body movements to a minimum. With the Sports mode activated, the dampers switch immediately to a firmer set-up ensuring excellent agility on smooth surfaces together with a further enhancement of steering precision. Whenever the system is set in this mode and detects a rougher road surface, in milliseconds, it will switch over to a softer set-up within the Sports control map in order to improve road contact. By pressing the Sports button, the driver also activates a special engine control map which increases torque by approximately 11 lb-ft from 3000 – 4250 rpm, and boosts engine power by almost 14 bhp.

Front axle adjustable to various settings

The front axle of the new 911 GT3 is based on the structure and configuration of the former model, while applying an even firmer set-up of the springs and dampers, as well as a stiffer anti-roll bar. A new feature on the GT3 is the PASM damper strut has an additional external thread and a height-adjustable spring plate, allowing an adjustment of the ride height, and fine-tuning of individual wheel loads on the race track. The new 911 GT3 also features cylindrical springs on the front axle with a linear control map. The geometric configuration of the springs and spring plates is based on racing spring standards, allowing relatively easy and straightforward adjustment of the suspension for motorsport events on closed circuits.

The support mount allows two wheel positions for road and racing tires with their different camber. Fine adjustment of wheel camber is provided by adjustment discs on the lower, split-track control arm. Like its predecessors, the 2007 911 GT3 features a tubular anti-roll bar on the front axle adjustable to five different positions. The bar is adjusted via alternate mounting points on the anti-roll bar bracket located on the thrust rods between the anti-roll bar itself and the wheel mounts. These options in adjusting the suspension set-up of the 911 GT3 are intended exclusively for motorsport, preparing the car in racing trim for the individual requirements of different tracks and circuits.

Rear axle with firmer mounts

In its basic configuration and features, the rear axle of the new 911 GT3 is the same as the rear axle on the current 911 Carrera, but with a firmer set-up. To fulfill the various demands made of the 911 GT3 in terms of motorsport, the rear axle has been upgraded at various points, including metal bushings replacing the usual rubber mounts for the longitudinal arms. Apart from giving the rear axle firmer support to the body of the car, this modification also raises the pivot point 6 millimeters. The result is further enhancement of the car’s kinematics with an even smaller change in wheel camber and caster when the springs are under pressure. Like on the front axle, the PASM damper strut on the rear axle features an additional outer thread and a height-adjustable spring plate. And last but not least, the tubular anti-roll bar is adjustable to three different positions allowing further finetuning of the suspension for racing requirements.

Variable steering for even greater agility in bends

The steering of the new 911 GT3 is the same as on the current 911 Carrera. With its variable transmission ratio, the steering improves the car’s agility particularly on winding roads, at the same time enhancing driving stability at very high speeds. With the steering wheel turned only slightly to the side, the steering transmission ratio is similar to the ratio on the former model, keeping the car calm and ensuring a smooth, forgiving reaction to rapid movements of the steering wheel at high speeds. Once the steering wheel angle increases to more than 30 degrees, the transmission ratio becomes increasingly direct, offering the driver greater agility on winding roads, particularly in tight bends. Yet another feature carried over from the Carrera models is manual adjustment of the steering wheel, enabling the driver to adjust the steering wheel by 40mm (1.57 in.) in terms of both height and reach.

A Porsche tradition of phenomenal brakes

A long-standing policy and consistent strength of Porsche sports cars is the use of brakes which greatly exceed the power of the engine. The new 911 GT3 naturally continues this intelligent concept with six-piston brake calipers on the front wheels firmly acting on the inner-vented, cross-drilled brake discs measuring 350 millimeters (13.78 in.) in diameter. New brake air spoilers and new air guidance blades ensure highly efficient ventilation and improved brake cooling.

The guidance blades direct the majority of the air flowing behind the radiators through the wheel arches directly to the brake system. To reduce the transmission of high brake temperatures to the hydraulic fluid, the pistons on the brake calipers are thermally disconnected and insulated by ceramic inserts. This protects the brake fluid from overheating even under extreme loads. The rear axle comes with new, larger brake discs also measuring 350mm (13.78 in.) in diameter. Interacting with fourpiston fixed calipers, the rear brakes are now able to convey higher stopping power and deceleration forces.

The new configuration of the brake system is based on experience gained in motorsports, and serves to make additional use of brake power on the rear axle from initial brake application, which due to the engine mounted at the rear, is when the loads acting on the rear axle are still relatively high. This high axle load is used to convey even higher brake forces to the road and to further shorten the car’s stopping distance. Like the current 911 Carrera 4 and Carrera 4S, the new 911 GT3 features a tandem power brake servo. The transmission of brake power, however, has been modified especially for the GT3, allowing the driver to more precisely apply braking power and improve the car’s driving dynamics accordingly.

PCCB® with new Arcus ceramic brake discs

Given its elevated competence at generating speed, the new 911 GT3 forms a perfect team with the optional Porsche Ceramic Composite Brakes (PCCB). Compared to brake systems featuring cast iron brake rotors, PCCB technology offers a number of advantages including faster brake response, a very high level of fade resistance thanks to the consistent frictional coefficient, and superior safety reserves under high loads.

The most important modification featured by the brake rotors (discs) is the Arcus design of the interior cooling ducts for improved brake ventilation, enhanced cooling of the brakes, and even higher rotor stiffness. At the same time the optimized composition of the brake material improves the brakes’ resistance to abrasion. The PCCB rotors on the front axle are now 30 millimeters (1.18 in.) larger than before, measuring 380mm in diameter (14.96 in.) but weighing less than before thanks to a brake cover previously made of steel but now cast out of aluminum. This reduces the weight of each brake disc by 900 grams, and the entire PCCB system weighs approximately 20 kg (44lb.) less than the standard cast-iron brakes.

New wheels running on a wide track

The 2007 911 GT3 comes standard with 19-inch light-alloy “GT3 Design” wheels running on special sports tires. To capitalize on the car’s lateral acceleration and roll stability, spacers on the rear axle broaden the car’s track by an additional five millimeters (0.20″ in.). The standard tires on the new GT3 were developed in close cooperation with Porsche’s suppliers, and feature a unique rubber compound on a fabric body specially engineered for these tires. Carefully tuned and matched to the new 911 GT3, the tires offer supreme lateral dynamic reserves particularly on dry surfaces, and the tires are fully suited for track outings.

The supreme quality of the GT3’s tires is borne out in particular by the substantial grip they offer also on a wet road, but with tread depth being smaller than usual, the risk of aquaplaning is greater on very wet surfaces and in the rain. The new 911 GT3 comes standard with a separate air pressure tester allowing the driver to quickly check tire pressure whenever necessary, for example when racing the car on the track, and a tire repair kit made up of a tire sealant and a tire pressure compressor is also included.

Light and Stable Chassis

One of the most important objectives in developing a genuine sports car is to optimize the car’s performance with low weight. Since this applies particularly to the GT models in the 911 model series, Porsche’s body engineers have combined components from two versions of the 911 Carrera in the new GT3: The body-in-white comes mainly from the 911 Carrera 4, while the outer shell of the body has been carried over from the 911 Carrera. The doors and luggage compartment lid are made of aluminum, the rear lid is an all-new construction made of extra-light plastic. One of the advantages of choosing the body structure of the four-wheel-drive Carrera was the option to fit in a 90-liter (19.8 Imp gal) fuel tank in lieu of the front axle transmission. And as on the current 911 Carrera 4 models, the new chassis serves to increase torsional stiffness over the former GT3 by 8 per cent, with flexural stiffness up by 40 per cent.

Six airbags featured as standard

The new 911 GT3, like the entire generation of new 911 models, comes with six airbags and energy-absorbing door pads including reinforcements in the doors. The airbag system is made up of two-stage full-size airbags for the driver and front 2007 Porsche 911 GT3 / 8 passenger, thorax airbags integrated in the seats at the side to protect the occupant’s upper body in a side-on collision, and head airbags housed in the upper door linings.

Striking wind-tunnel styling

The front end of the 2007 911 GT3 is characterized by extra-wide cooling air intakes positioned at the outer edges. These air scoops give the GT3 a particularly powerful look, and at the same time ensure a consistent supply of cooling air. Through their design and configuration with vertically arranged bars, the air intakes add to the unique look and character of the GT3 within the 911 model lineup. Protruding slightly, the centre air intake extends all the way to the “lip” of the spoiler, forming a slight wedge to enhance the aerodynamic efficiency of the car. The joint between the front section and the spoiler lip serves to accentuate the central cooling air intake. A striking design feature of the new 911 GT3 is the additional air outlet in front of the luggage compartment lid. Within the current model series, this feature is exclusive to the new GT3, guiding the flow of air from the central radiator up, and not beneath the car. Viewed from the side, the GT3 stands out immediately as a proud member of the 911 model series.

The most distinguishing features are the low position of the car, the muscular rear wing fitted firmly in place, and the special design of the wheels. The new single-piece 19-inch GT3 wheels are an evolution in the design of the 18-inch wheels featured on the former model. The fixed rear wing is a traditional feature of all GT3 models and, together with the front section, stands out as the most striking aesthetic highlight of the car. The vertical sections on the wing follow the contours of the car’s rear section, with their curvature perfectly matching the shape of the rear wheel arches.

The additional streamlining flap at the bottom of the wing’s vertical panels not only integrates the rear wing into the overall design of the car, but also makes a significant contribution to the aerodynamic performance of the new 911 GT3. The new 911 GT3 comes for the first time with its own specially designed rear end, featuring centrally mounted tailpipes, plus additional air outlet openings at the rear. The twin tailpipes stand out clearly from their position in the middle of the rear clip, and their larger diameter gives the new GT3 a particularly powerful look from behind.

This design feature has been carried over from the 911 Carrera Cup cars raced for the first time last season, and serve not only to provide a truly distinctive look, but also to optimize the aerodynamic flow of the exhaust system. Proceeding from the experience gained with the 911 GT3 Cup in motorsport, Porsche’s engineers carefully optimized the car’s aerodynamics in the wind tunnel. Downforce is provided throughout the car’s speed range by the front and rear sections, the shells in the wheel arches, the rear lid and wing, and the underbody panels. The new front end, with its separate spoiler lip and the new, upper air exhaust vent leading out of the central radiator, reduce the flow of air beneath the car. The optimum position of the cooling air openings, in turn, guides air coming out from behind the side radiators straight to the brakes in the interest of enhanced cooling.

This makes a significant contribution in reducing lift forces on the front axle, while on the rear wheels small spoilers improve air flow and reduce lift. The aerodynamic improvements made at both the front and the rear of the car are carefully matched and coordinated with one another to ensure optimum balance on the front and rear axle. Compared with the former GT3, the rear wing offers an even higher standard of aerodynamic efficiency and generates downforce without increasing aerodynamic drag, even at speed.

Apart from the new profile of the rear wing, this superior standard of aerodynamics is attributable to the flap at the bottom of the box-shaped wing and the winglets at the side. When racing the car on the track, the rear wing may be adjusted by either 3 or 6 degrees. Apart from lowering the car’s centre of gravity, the lower overall position of the new 911 GT3 reduces the height of the car by approximately 30 millimeters (1.18 in.) versus the current 911 Carrera, and also serves to improve the GT3’s aerodynamics and streamlining. The lower body reduces the size of the frontal area (with a related improvement in air drag) and the flow of air beneath the car (with a reduction in lift). Like the new-generation 911 Carrera models, the new 911 GT3 comes with extensive panels on the underbody for superior aerodynamics. Additional vents in the rear end of the underbody cover serve to cool the rear brakes.

An Interior for the Sophisticated Sportsman

The interior of the new 911 GT3 is based on the new-generation 911 Carrera and at the same time boasts components carried over from both the former 911 GT3 RS and the Carrera GT.

The interior of the 911 GT3 is characterized by a steering wheel rim as well as the gearshift and handbrake knobs all finished in Alcantara. The middle sections on the seats also come in this high-quality, and grippy material. As an option, the new 911 GT3 is available in either black or dark grey leather. And should the customer wish to personalize his car to an even higher standard, a wide range of additional leather and carbon features is also available. As yet a further sign of distinction, the new 911 GT3 comes with an instrument cluster reminiscent in its design of the Carrera GT. The needles and scales are finished in yellow and the rev counter is highlighted by a titanium-colored face proudly bearing the “GT3” logo.