The Audi R8 e-tron – High Power with an Electric Drive

The Audi R8 e-tron is a high-powered sports car with a purely electric drive. Its four engines provide a total power of 230 kW (313 hp) for splendid driving performance. They can be individually actuated – for an entirely new developmental stage of the permanent four-wheel drive.

- Seating capacity: 2

- Top Speed: 124 mph / 0–60 time: 4.8 sec.

- Power: 313 hp

- Range: 154 miles

- Availability: Concept; limited number, available in U.S. by 2012

- Price: Not available

The concept

The four asynchronous motors – two each on the front and rear axles – make the Audi R8 e-tron a quattro. Power is transmitted to the wheels via the single-staged transmission and short input shafts. With a peak output of 230 kW (313 hp) and with up to 4500 Nm (3319.03 lb-ft) torque at the wheels available from a standstill, the R8 e-tron delivers breathtaking driving performance. It catapults from 0 to 100 km/h (62.14 mph) in just 4.8 seconds.

The technology demonstrator enveloped by the R8 belongs to the top league of electric sports cars. Its package does justice to the specific qualities of the new technology in all details. The large, fluid-cooled lithium-ion battery and the power electronics, for example, lie directly behind the passenger compartment. The result is an optimal center of gravity and a load distribution of 42:58 between the front and rear axles – just like the series production R8 with its 5.2 liter FSI.

The R8 e-tron provides a glimpse into Audi’s philosophy of electric mobility. Extending far beyond the battery technology and the replacement of an internal combustion engine by an electric driveline, the concept is holistic. The complex interaction of all components crucially affects the factors of efficiency, range and road capability.

The Energy Supply

The rechargeable lithium-ion battery installed in the Audi R8 e-tron consists of single cells with a high energy density connected in parallel and in series, and ensures a high output. Under all the general constraints, an intelligent battery management system makes the energy optimally available. The 550 kg (1212.54 lb) battery stores 53 KWh of energy, with the usable share amounting to 42.4 kWh. In the final design stage of the Audi e-tron, the battery will enable a range of about 250 km (155.34 miles) when operated in the NEDC cycle.

For recharging the battery a household current with 230 volts suffices; the process takes six to eight hours for a fully discharged battery. A high-voltage current will reduce the charging time to about two and a half hours. Thanks to recuperation the battery of the Audi R8 e-tron is also recharged on the road during the braking and deceleration phases – the four electric motors are able to recover a considerable part of the energy.

The Driving Dynamics

The distribution of the electric drive torque in the R8 e-tron distinctly favors the rear axle. Like the standard Audi R8, about 70 per cent of the power acts at the rear in regular operation, with the remaining 30 per cent going to the front wheels. Should slip occur at an axle, this balance changes in a fraction of a second – so that the electrically driven high-powered sports car embodies the fundamental strength of quattro technology.

The R8 e-tron also manages the lateral dynamics through its four motors. They allow so-called torque vectoring, the selective acceleration of individual wheels and therefore active distribution of torque. Understeering and oversteering can be compensated with ultra precision by small power boosts and brake interventions. The electrically driven high-powered sports car retains exemplary neutrality even at maximum lateral acceleration, hurrying along curves as if on rails.

The running gear employs double triangular control arms at the front axle and trapezium links made of forged aluminum components at the rear axle – a configuration that has proven its merit in motor sports as an optimal layout for high dynamics, maximum precision and exact intrinsic steering behavior. Notwithstanding the firmness of the springs and shock absorbers, they still afford good comfort. The rack and pinion steering with its direct gear ratio provides finely differentiated feedback. The steering is electro-mechanically assisted depending on the speed. The Audi R8 e-tron rolls on 19 inch wheels.

The Design and the Package

The Audi R8 e-tron presents a broad and brawny figure on the road; the trapezoid of the single frame grill governs the front section, flanked by large air inlets. 1.90 meters (6.23 ft) in width and only 4.43 meters (14.53 ft) in length and 1.25 meters (4.10 ft) high – these are the proportions of a super sports car. A 2.65 meter (8.69 ft) wheelbase leaves a generous amount of space for the driver and front passenger.

A consistently lightweight design is a crucial precondition for efficiency and range, especially among electric cars. For the R8 e-tron Audi engineers exploited one of the company’s core competences: the body is aluminum; designed with Audi Space Frame technology (ASF), it weighs less than

200 kg (440.92 lb). The lightweight body is an important reason why the Audi R8 e-tron weighs in at just 1600 kg (3527.40 lb).

The Interior and the Control Concept

Unlike the standard model, the Audi R8 e-tron has a graphic display for showing the driving mode. The display lies between the two large round instruments, with the left one presenting the recuperation status and the output. The driver can select the level of recuperation by means of one-touch switches on the steering wheel, and thereby directly influence energy recovery and the braking power of the electric motors in order to increase the e-tron’s range.

Series Production

Audi will be bringing a limited edition of the R8 e-tron to the roads in late 2012. It will be built at quattro GmbH in Neckarsulm, which has extensive experience in the construction of exclusive sports cars.

Audi e-tron Spyder

Audi presents the Audi e-tron Spyder, the study of an open sports car, at the fall 2010’s largest auto show. The show car, with plug-in hybrid drive, is 4.06 meters (13.32 ft) long, 1.81 meters (5.94 ft) wide and only 1.11 meters (3.64 ft) high. The two-seater is equipped with a 221-kW (300-hp) twin-turbo V6 TDI at the rear axle and two electric motors producing a total of 64 kW at the front axle.

The Audi e-tron Spyder’s low total weight of only around 1,450 kilograms (3,196.70 lb) combined with the high-torque TDI and the two electric motors results in respectable performance. The car accelerates to 100 km/h (62.14 mph) in just 4.4 seconds, and top speed is electronically governed at 250 km/h (155.34 mph).

The e-tron Spyder can combine the powerful torque of its TDI – the diesel engine generates 650 Nm (479.42 lb-ft) and the total of 352 Nm (259.62 lb-ft) of its two electric motors during acceleration in a process known as “boosting.”

The intelligent distribution of power allows for optimal dynamics in every situation. The targeted application of power to the front wheels improves longitudinal dynamics while also improving lateral dynamics when cornering. This is because torque vectoring – the as-needed distribution of torque between the left and right wheels of the two axles – enables an exhilarating degree of driving precision and excellent agility.

Thanks also to its low weight, short wheelbase and perfect 50:50 weight distribution for dynamic handling, the Audi e-tron Spyder has all the drivability of a go-kart – good on bends and neutral right up to the very high handling limit.

The combination of a highly efficient TDI and electric drive also provides for excellent fuel economy and amazingly low emissions. The Audi e-tron Spyder requires on average just 2.2l diesel/100 km (106.92 US mpg), corresponding to CO2 emissions of 59 g/km (94.95 g/mile). A range of more than 1,000 kilometers is possible with the 50-liter (13.21 US gallons) tank.

The open sports car can also drive strictly on electric power and thus with zero emissions over distances of up to 50 kilometers (31.07 miles), such as in urban areas. The top speed of 60 km/h (37.28 mph) is just fine for normal driving.

Design

The Audi e-tron Spyder features what is without a doubt the most advanced and simultaneously the most consistent evolution of the current Audi design language, while also providing initial hints at the design language of future Audi sports cars. It reinterprets the most important design elements that already characterized the previous e-tron concept vehicles. This also ensures the necessary formal differentiation to the purely electric-powered Audi e-tron shown at the 2010 Detroit Motor Show.

1.81 meters (5.94 ft) wide, just 4.06 meters (13.32 ft) long and only 1.11 meters (3.64 ft) in height: these are the classic proportions of an open, high-performance sports car. Compared to the coupé concept car in Detroit, the length and width have increased by 13 cm (5.12 in) and 3 cm (1.18 in), respectively, to underscore the sporty aspiration of the design. This further enhanced the powerful and compact overall appearance that characterizes both vehicles and links them to the sportiest production Audi, the R8.

Due in no small part to the short wheelbase of only 2.43 meters (7.97 ft) – 22 cm (8.66 in) shorter than that of the R8 – the body of the e-tron Spyder comes across as extremely stocky.

In an apparent homage to motor sports, the frameless side glass surfaces taper downward toward the rear. They form a unit with the windshield, which is strongly bowed and inclined like the visor of a helmet.

Another element borrowed from race cars characterizes the hood: the wide central air inlet, whose curve further accentuates the dynamics of the car’s front end and provides a visual and functional link to the Audi R8 LMS customer race car. The carbon application that is mounted flush in the front and side windows and wraps completely around the glass testifies to the design and manufacturing expertise that went into the car.

The front the silhouette of the e-tron Spyder are characterized by a sharp, sweeping line that immediately identifies the two-seater as an Audi. The sharply tapered front end lends the Audi e-tron Spyder show car a distinctly wedge-like basic shape. The trapeze of the single-frame grille dominates the distinctly wedge-shaped front end and is flanked by two large air intakes. They serve as cooling intakes for the electric drive system and also for the TDI engine at the rear of the vehicle.

Above, the grille merges into the flat strips of the adaptive matrix beam headlight modules with their three-dimensional clear glass covers that follow the contour of the functional elements.

All light units use ultra-efficient LED technology. As with the R8 and the e-tron sports car concept cars, the trademark four rings are located above the single-frame. Beneath the trademark is the charging station for the batteries. The rings disappear beneath the front hatch, exposing not just the charging plug but also a display showing the charge state and a map graphic indicating the current electric range.

Another distinctive feature of this show car are the 20-inch wheels, that take the blade design of the first e-tron show car and refine it into a three-dimensional turbine design. The wheels combine the lightweight materials aluminum and carbon into a design that is both visually pleasing and very effective aerodynamically. The 66 individual components comprising each individual wheel of the e-tron Spyder are indicative of just how complex they are.

The flanks sport familiar contours in a new form. Unusually sharply defined edges frame the smooth side surfaces while simultaneously separating horizontal from vertical areas.

The shoulder line frames the lines of the strongly contoured wheel wells even more distinctly than in the Audi R8 and combines them with the upper edge of the vehicle body. Particularly when viewed from the back, the e-tron Spyder appears even more pronouncedly horizontal and more strongly oriented toward the road.

An impression that is also created by the characteristic sills with a new cut and is picked up by the spoiler and diffuser at the front and rear of the car. Carbon elements borrow from motor sports to set special accents here as well. Carbon is also used on the engine cover in the rear and in license plate and lighting frame, which also includes the air outlets below the lateral light units.

The contrast of materials is reminiscent of a race car. The essential functional elements of the chassis and the vehicle body are done in carbon, while the body as a cover sports a classic paint finish. This illustrates the formal “shell-and-core” principle that defines the e-tron Spyder particularly clearly.

Thanks to an opening in the hood, even the longitudinal TDI mid-engine is a visible technological element surrounded by matt and glossy carbon surfaces, aluminum and leather. This combination of materials links the exterior with the interior of the vehicle.

Behind the seats are two cowls that gradually taper toward the rear and also flank the opening for the TDI engine and the implied cooling fins of the engine cover. They also contain the normally hidden rollover bars, which like in the production R8 Spyder shoot up within milliseconds and lock into place in the event of an emergency.

Interior

Visual and functional references to the fundamental concept of lightweight construction characterize the purist interior design. They establish a connection between proven Audi genes and new formal hallmarks. Typical for the Audi design idiom is the reduction of the architecture, controls and information output to the essentials in favor of a tidy overall impression.

The slim dash has a curve that extends laterally into the door panels. With no need to allow for a transmission, shifter and cardan tunnel, the designers again took advantage of the opportunity to create a particularly slim and lightweight center tunnel and convex, arching center console for the e-tron Spyder with hybrid drive. The only control element other than that of the MMI is the flush-mounted selector lever for the automatic transmission, which extends upward from the tunnel when the vehicle is started.

The cockpit of the Audi e-tron Spyder is also oriented toward the driver – a further characteristic Audi trait. Instead of the classic instrument cluster, the concept car is equipped with a large, display with integrated MMI functions and flanked by two round dials. The MMI can be controlled via a touch-sensitive control panel on the steering wheel – an element inspired by modern smartphones. It can also be controlled via the MMI control unit (MMI touch) on the center console. The steering wheel itself is clearly flattened off at both the top and bottom, in a clear reference to motor sport. Speed is displayed in digital form only. The dial instrument with information about the drive system can be chosen via the menu item “Drive.”

Besides information about the speed, the revs of the combustion engine and the electric drive, the central display also provides all of the key information from the infotainment and navigation systems.

Characteristic for the concept of the Audi e-tron Spyder is the near total elimination of switches and components such as the ignition. The climate control unit is located to the right above the steering wheel. The display provides temperature and ventilation information. Again drawing inspiration from a smartphone, the system is operated by means of a touch-sensitive control panel.

The equally racing-inspired lightweight bucket seats combine excellent lateral support with comfort. Contrasting colors and stitching delineate the various zones of the interior. The colors and the high-quality materials combine elegance and sportiness.

ASF body

Systematic lightweight construction is a crucial prerequisite for efficiency and range, while also being the primary foundation for exhilarating driving dynamics. The Audi development engineers drew on the core competence of the company for the Audi e-tron Spyder. The body structure is based on Audi Space Frame (ASF) technology and was realized as a hybrid construction, with the hood and numerous aerodynamic components made of carbon.

In ASF technology, the body’s supporting structure is made of extruded aluminum sections and die-castings. Aluminum panels are incorporated into this skeleton to form a positive connection and perform a load-bearing role. Each individual component of the ASF space frame is optimized for its specific task by the use of widely differing shapes and cross-sections, combining maximum stability with minimal weight. Despite the complex drive system layout with two electric motors and their respective drive systems plus the TDI engine, the Audi e-tron Spyder show car only weighs around 1,450 kilograms (3,196.70 lb).

Engines and transmissions

Audi has long proven the perfect synthesis between a highly advanced sports car and TDI technology. With the TT, Audi become one of the first manufacturers anywhere in the world to successfully bring a diesel sports car to market, a decade after the Audi Cabriolet paved the way for diesel engines in this segment. And the Audi R8 TDI Le Mans concept car was the first supercar to be fitted with a twelve-cylinder diesel engine with 500 hp and 1,000 Newton meters (737.56 lb-ft) of torque.

The Audi e-tron Spyder also draws on this recipe for success – albeit in a revolutionary new combination. This marks the first use of a new generation of the six-cylinder, 3.0 TDI that breathes through two turbochargers and produces 221 kW (300 hp). That is another 50 hp more than the previous stage, which debuted a few months ago in the new Audi A8.

Peak torque of 650 Newton meters (479.42 lb-ft) is unusually high, even in the sports car segment. The mid-mounted, longitudinal 3.0 TDI engine drives the rear wheels via a seven-speed dual-clutch transmission.

Another innovation is the coupling of the TDI with the electric drive of the front axle. Two asynchronous electric motors with a total output of 64 kilowatt (88 hp) and peak torque of 352 Newton meters (259.62 lb-ft) combine with the 3.0 TDI to give the Audi e-tron Spyder the performance of a high-performance sports car. It accelerates from 0 to 100 km/h (62.14 mph) in 4.4 seconds. Top speed is electronically governed at 250 km/h (155.34 mph).

The drive’s characteristic is even more exciting than the abstract numbers. Thanks in no small part to the fact that the peak torque of the electric motors is available immediately, the e-tron Spyder accelerates with catapult-like thrust. Short passing maneuvers on interurban roads can be pulled off as spurts that are every bit as relaxed as they are fun, even without having to downshift.

The noise level of the low-revving TDI is typically low. The six-cylinder unit behind the occupants issues a sonorously sporty growl under load, but never becomes loud. A surprising effect also present in the Le Mans-winning Audi R10 and R15 race cars, which are also powered by TDI engines.

The benefits of this special form of hybrid drive – the coupling of a high-torque, high-efficiency TDI engine with the electric motors – are by no means limited to the dynamic potential of the Audi e-tron Spyder, however. The open two-seater also sets new standards in its class for fuel consumption and environmental characteristics. The 300-hp TDI consumes on average just 2.2 liters of diesel per 100 kilometers (106.92 US mpg), which corresponds to CO2 emissions of only 59 g/km (94.95 g/mile).

The full-hybrid Audi e-tron Spyder has also mastered the discipline of zero-emission driving. In residential and other urban areas, the driver can activate the electric drive by itself. The 9.1-kwH battery at the front of the car has enough power for up to 50 kilometers (31.07 miles). And with a top speed of up to 60 km/h (37.28 mph), the e-tron Spyder is also able to move along smartly in city traffic.

Chassis

The normal distribution of the tractive power is clearly biased toward the rear axle in accordance with the weight distribution of the e-tron Spyder and the dynamic shift in axle load during acceleration. Similar to with a pure mid-engine sports car, roughly 75 percent of the torque goes to the rear and 25 percent to the front. If an axle slips, this balance can be varied thanks to the central control of the entire drive system in combination with the ESP. The hybrid vehicle from Audi thus enjoys all of the advantages of quattro technology.

The combination of the mid-mounted TDI engine and the two electric motors at the front axle also make it possible to intelligently control the lateral dynamics of the e-tron.

Similar to what the sport differential does in conventional quattro vehicles, torque vectoring – the targeted acceleration of individual wheels – makes the e-tron Spyder even more dynamic while simultaneously enhancing driving safety. Understeer and oversteer can be corrected by not only targeted activation of the brakes, but also by precise increases in power lasting just a few milliseconds. The concept car remains extremely neutral even under great lateral acceleration and hustles through corners as if on the proverbial rails.

The chassis has triangular double wishbones at the front axle and a trapezoidal-link rear suspension made of forged aluminum components – a geometry that has proven in motorsports to be the optimal prerequisite for high agility, uncompromising precision and precisely defined self-steering behavior. A taut setup was chosen for the springs and shock absorbers, but it is still very comfortable.

The direct rack-and-pinion steering gives finely differentiated feedback. Its electromechanical steering boost varies with speed, so that the e-tron Spyder only has to provide energy while steering, and not while driving straight ahead.

As befitting its status, the Audi concept car rolls on 20-inch tires with a new blade design. 245/30 tires up front and 265/30 tires in the rear provide the necessary grip.

A look inside the development workshop

- quattro GmbH builds technology platform at satellite site in Biberach

Werner Frowein, Managing Director of quattro GmbH: “The staff is highly skilled in small series production.”

Franciscus van Meel, Head of Audi Electric Mobility Strategy: “The R8 e-tron reflects the strengths of our brand and offers an extremely sporty take on the subject of electric mobility.” Neckarsulm, May 12, 2011 – The first all-electric Audi will be built at the Neckarsulm site, with a small production run of the R8 e-tron sports car to hit the roads in late 2012. quattro GmbH is currently building the first technology platform for the electric model at the Neckarsulm plant’s satellite site in Heilbronn-Biberach. Specially qualified employees are borrowing from the series production of the successful Audi R8 mid-engine sports car as they assemble the R8 e-tron at the development workshop. The 122nd Annual General Meeting of AUDI AG in Neckarsulm gave business and product journalists their first opportunity to look inside the development workshop for the Audi R8 e-tron. “With the R8 e-tron, we are showing how inspiring electric mobility can be. Every system in this car has been tuned for maximum performance and range,” says Franciscus van Meel, Head of Electric Mobility Strategy at AUDI AG. “The R8 e-tron is a very important project for Audi because the competence and experience we glean from it will later flow into the large volume production of electric automobiles.” The expectation is that e-tron will become a synonym for advanced electric mobility, just as the term “quattro” today stands for pioneering all-wheel drive. “We want to be the leading premium manufacturer of electric vehicles by 2020,” says van Meel. Systematic lightweight construction is one of the key preconditions for efficiency and range in electric vehicles. The Audi development engineers are therefore drawing on one of the company’s core competences for the R8 e-tron: The body is

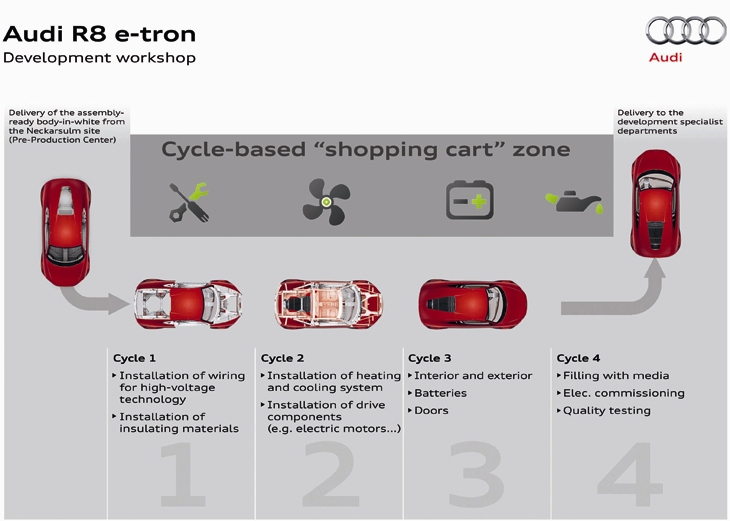

aluminum; thanks to Audi Space Frame technology (ASF), it weighs barely more than 200 kg (441 lb). The lightweight body is an important reason why the R8 e-tron weighs in at just 1,600 kg (3,527 lb). Employees at the Pre-Production Center in Neckarsulm and quattro GmbH are currently building the first technology platforms for the electric car. “The successful production of our Audi R8 high-performance sports car has given the employees of quattro GmbH a high level of competence in the area of small production runs and sports car manufacture,” explains Managing Director Werner Frowein. The aluminum body of the technology platform is being built in conditions very close to those for volume production in the body shop for the R8 mid-engine sports car. Specific assemblies for the electric model, such as the center tunnel, are being produced by the Pre-Production Center in Neckarsulm. The R8 e-tron also goes through the coating process with the volume model. The technology platform is then sent to the satellite site in Heilbronn-Biberach for final assembly. “The production process is designed so that we can exploit synergy effects from R8 volume production,” explains Frowein. For example, the sophisticated logistics concept that supplies the R8 factory with parts is also used for the body of the technology platform. Pre-picked components are delivered to the employees in “shopping baskets.” The parts are installed in the vehicles in a defined sequence in four cycles. “Small-series production places great demands on our employees,” says Frowein. This is why the development workshop is staffed with experienced employees who worked in R8 series production, where they gleaned key competence in small-series production. “The development workshop staff are specially qualified for high-voltage vehicles,” explains Andreas Heine, quattro GmbH project manager for the body of the R8 e-tron. They are trained in three stages – depending on their function and technical training – to work with the high-voltage technology.

The basic level is sensitization for driving and working on high-voltage vehicles. The training then builds on this to qualify the workers as electronics experts for defined activities. Finally, the extended training as Certified Electronics Specialists for Automotive Technology provides the employees with the expertise required to perform the complete range of activities associated with high-voltage models. AUDI AG is investing more than €5 billion in the two German sites at Ingolstadt and Neckarsulm between 2011 and 2015. A majority of this investment will flow into the development of new products and into future technologies such as electric and hybrid drive systems.